| |

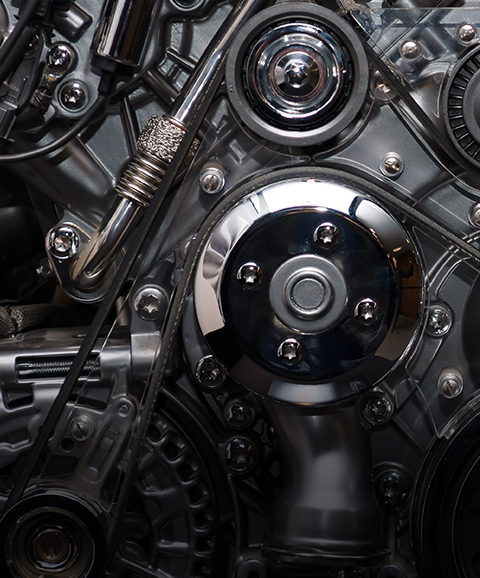

CUSTOM BLACK CHROMATE PROCESS FOR THE AUTOMOTIVE INDUSTRY

Many of our customers have come to us from the automotive industry, where consistent appearance can be everything.

Such was the case when an automotive industry client asked Micro Metal Finishing to develop a custom black chromating process to produce a consistent finish on automotive parts. As is our practice, we met with the customer and carefully listened to their requirements. We then sought out high-quality suppliers for the necessary materials and equipment, after which we installed the control system.

The problem is that the customer was seeking a consistent finish from trivalent black chromates, which can have a wide range of appearances. Furthermore, we knew that trivalent black chromate finishes did not lend themselves to high appearance standards. Following careful research, however, we discovered that to fulfill our customer's wishes, we would have to develop extremely tight controls of the trivalent black chromate solution's pH. Our team decided that the best way to control the pH solution was with the addition of two different chemical components, which would simultaneously control the pH and concentration of the plating solution. To that end, we installed a computerized control system that constantly measures the solution and precisely adds correct proportions of the two chemicals whenever necessary. In addition to appearance, sample parts had to survive a very demanding 800 hour salt spray test to determine their corrosion resistance, which they did with flying-and consistent-colors.

In an instance such as this where research and knowledge of coating chemistry was required to satisfy our customer, Micro Metal Finishing was able to deliver. The work was overseen by a highly trained lab manager, but a maintenance manager with over 40 years of experience in the industry. If this is the level of expertise you want on your next finish project, contact us directly for further information.

|

|

| |